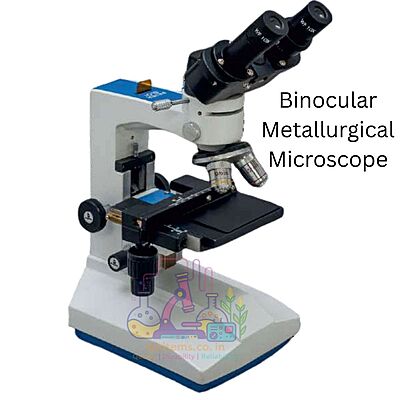

Binocular Metallurgical Microscope MM-3 - ALMICRO

The ALMICRO MM-3 Binocular Metallurgical Microscope is an advanced surface inspection system designed for accurate metallurgical analysis with enhanced viewing comfort and higher magnification capability. Compared to the MM-2 inclined monocular model, the MM-3 upgrades the observation system to a binocular head with hard-coated prisms, allowing fatigue-free, extended inspection and improved depth perception during material evaluation.

The MM-3 features a bright-field horizontal illuminator with centering provision, delivering more uniform and controlled illumination than basic metallurgical microscopes. Its special graduated mechanical stage enables precise sample movement and repeatable positioning, improving measurement accuracy over earlier non-graduated or basic stage designs.

With standard objectives up to 45× and optional magnification extending to 450×, the MM-3 offers a significantly wider magnification range than MM-2, making it suitable not only for routine surface inspection but also for detailed microstructural examination. Variable light intensity control through a heavy-duty transformer further enhances contrast optimization for reflective specimens.

Key advantages over MM-2 inclined monocular model,:

Binocular viewing replaces monocular inclined tube for better comfort

Higher achievable magnification range (up to 450×)

Improved ergonomics for prolonged metallurgical inspection

Better suited for research, QA, and industrial labs

Ideal for:

Metallurgy labs, quality control departments, material science training, and industrial inspection environments requiring higher magnification and binocular observation.

Customize

Product Details

Binocular Metallurgical Microscope – MM-3

Product Overview

The MM-3 Binocular Metallurgical Microscope is designed for precise reflected-light examination of opaque materials such as metals, alloys, and industrial components. Equipped with a binocular head with hard-coated prisms, bright field horizontal illumination, and a graduated mechanical stage, the MM-3 delivers accurate surface analysis for metallurgical laboratories, quality control departments, and material research facilities.

Key Features & Benefits

| Feature | Benefit |

|---|---|

| Binocular Head with Hard-Coated Prisms | Provides comfortable viewing with high contrast and reduced eye strain |

| Bright Field Horizontal Illumination | Ensures uniform reflected light for clear surface structure observation |

| Quadruple Revolving Nosepiece | Allows quick switching between objectives during analysis |

| Special Graduated Mechanical Stage | Enables precise positioning and controlled movement of samples |

| Heavy-Duty Variable Light Transformer | Stable illumination control for consistent image quality |

| Wide Magnification Range | Suitable for detailed grain structure and surface defect analysis |

Optical & Mechanical Specifications

| Parameter | Specification |

|---|---|

| Observation Head | Binocular, hard-coated prisms |

| Illumination | Bright field horizontal reflected illumination |

| Nosepiece | Quadruple revolving |

| Stage | Special graduated mechanical stage |

| Light Control | Variable control via heavy-duty transformer |

| Eyepieces | WF10× (paired) |

| Objectives (Standard) | 10×, 45× |

| Optional Objectives | 5×, 100× |

| Magnification Range | 100× to 450× |

Applications

| Field | Usage |

|---|---|

| Metallurgical Laboratories | Microstructure and grain boundary analysis |

| Material Science | Surface and phase examination |

| Quality Control | Defect detection and coating inspection |

| Industrial Research | Failure analysis of metal components |

| Educational Institutes | Metallurgy and materials engineering training |

Packaging & Delivery

| Item | Details |

|---|---|

| Packaging | Inner Thermocol / Styrofoam Packing |

| Outer Packing | Heavy-duty Cardboard Box |

| Delivery | Secure and damage-protected shipping |

Specifications

- Eye Piece TypeBinocular

- Viewing HeadHard-Coated Prism Binocular Head

- Eye PieceWF10× (paired)

- NosepieceQuadruple revolving

- StageSpecial graduated mechanical stage

- FocusingSeparate coarse and fine adjustment

- IlluminationVariable control via heavy-duty transformer

- Objectives10× & 45×

- Total Magnification100× to 450×

- Light ControlVariable control via heavy-duty transformer

- PackagingSecurely packed with inner thermocol/styrofoam protection and a sturdy outer cardboard box to ensure safe transportation

- Special AttachmentsOptional Objectives - 5× & 100×